Deck Foam

Deck foam for fire extinguishing

Foam for fire protection purposes is an aggregate of air-filled bubbles formed from aqueous solutions, and is lower in density than the lightest flammable liquids. It is mainly used to form a coherent floating blanket on flammable and combustible liquids to prevent or to extinguish fires by excluding air and cooling the fuel. It also prevents re-ignition by suppressing formation of flammable vapours. It has the property of adhering to surfaces, providing a degree of exposure protection from adjacent fires.

Foam is used as a fire prevention, control, or extinguishing agent for flammable liquid in tanks or processing areas. Foam solution for these hazards may be supplied by fixed systems or portable foam generating systems.

Foam types

The principal use of foam is to extinguish burning flammable or combustible liquid spills or tank fires by developing a coherent coolant blanket. Foam is the only permanent extinguishing agent used for fires of this type. Its application allows fire fighters to extinguish fires progressively. A foam blanket covering a liquid surface is capable of preventing vapour transmission for some time, depending on its stability and thickness.

Fuel spills may be rendered safe by foam blanketing. The blanket may be removed after a suitable period of time. Foam is used to diminish or halt the generation of flammable vapours from non-burning liquids or solids, and to cut off access to air for combustion. The water content of foam cools and diminishes oxygen by steam displacement.

Foam is also used to fill cavities or enclosures where toxic or flammable gases may collect. Foam solutions are conductive and therefore not recommended to be used for electrical fires.

Foam concentrate types

- Protein foam concentrate. It is diluted with water to form 3% to 6% solutions depending on the type and, in general, it is only used for crude oil fires.

- Fluoroprotein foam concentrate is very similar to protein foam concentrates. It may also deposit a vaporisation preventing film on the surface of a liquid fuel. It is diluted with water to form 3% to 6% solutions depending on the type, and is used for crude oil or refined oil products where a higher degree of protection is preferred.

- Special ‘alcohol type’ foam concentrate forms a foam that has an insoluble barrier in the bubble structure which resists break down at the interface of the fuel and foam blanket. It is used for fighting fires in water solution and certain flammable or combustible liquids and solvents that are destructive to regular foam. Mainly used for protection onboard chemical tankers.

- Synthetic foam concentrate includes: AFFF and medium and high expansion foam concentrates are used to produce foam or foam-to-solution volume ratios from 20:1 to approx. 1000:1 and are used for local protection and engine room hi-ex systems.

SOLAS rules

For ships carrying chemicals or oils in bulk, SOLAS/IMO require a fixed deck foam system for extinguishing fires on deck or in tanks.

In principle, the systems required are identical; however, for chemical tankers, IMO type 2 and 3, the foam system is considerably larger than for crude oil tankers, due to the higher risk of fire in chemicals.

Design figures

Oil tankers

The foam system capacity shall be a minimum of the largest of the entire cargo tank deck covered with 0.6 l/ m2/min. or 6.0 l/m2/min. for the largest cargo tank.

Chemical tankers

The foam system capacity shall be a minimum of the largest of the entire cargo tank deck covered with 2.0 l/m2/min. or 20 l/m2/min. for the largest cargo tank.

System description

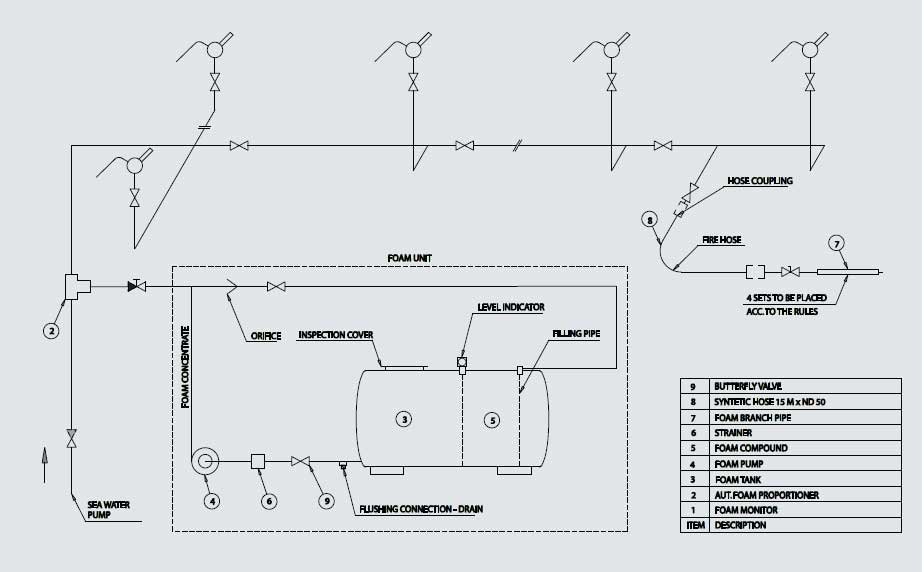

All foam systems, consist of a water supply, foam liquid storage, a proportioning device and a distribution system.

The water supply pump(s) provide(s) a certain capacity of seawater to the deck foam system, and is/are supplied by the ship’s fire pumps.

The foam liquid is stored in a tank. The tank must be complete with vent, contents gauge, and access manhole. The foam is delivered via a high pressure foam liquid pump to the automatic foam liquid proportionator, which will accurately proportionate foam liquid at 3% to 6% to the seawater flow, irrespective of flow rate or pressure.

For satisfactory operation of the proportionator, foam liquid must be supplied with a minimum pressure of at least 10 metres head higher than the inlet water pressure under all load conditions. The electrically driven foam liquid pump is provided for this purpose.

Foam solution is supplied to the deck monitors and hand lines by the deck main fitted with isolating valves. Each monitor is isolated from the main supply pipe by means of butterfly valves, which are normally closed.

Four portable foam-making branch pipes are provided. Each branch pipe has a solution rate of 400 l/min.