HPCO2 Fire Suppression System

Introduction

Carbon Dioxide Gas : Under normal atmospheric temperature and pressures, carbon dioxide exists as a colorless, odorless gas which is about 1.5 times heavier than air. Carbon dioxide will not burn or support combustion and will not sustain life. When confined within a suitable pressure vessel and depending on temperature and pressure conditions, carbon dioxide can exist in any of three stages of matter; solid, liquid and gas.

High Pressure Carbon Dioxide System : High pressure CO2 system is a specialized fire extinguishing system designed to maintain the carbon dioxide supply at 21º C and 850 psig in strength alloy steel cylinders. The cylinders contain the CO2 required to protect the largest single hazard. On large hazards where several cylinders are required, a manifold is used to connect each cylinder by means of flexible hoses and check valves.

Cylinder valves control the CO2 flow to the hazard through properly sized pipe, terminating in nozzles that apply the CO2. Flow rate is controlled by nozzle orifices as well as pipe sizes. The cylinder master valves are electronically operated and the slave valves are pressure actuated. The master valves can be automatically and/or manually operated.

CO2 Extinguishing System Most Ideal For Protecting :

- Paint Manufacturing & Painting Booth

- Transformer & substation

- Rolling mill & Turbine

- CNC Machine

CO2 high pressure fire extinguishing system

Characteristics:

- Suitable for extinguishing in closed spaces like engine rooms, auxiliary rooms, cargo holds, etc.

- Extinguish the fire within a short time and leave no residue after extinguishing: shut-down time after a fire will be reduced to a minimum

- Suitable for extinguishing fires in combustible liquids, gases and electrical equipment, and for extinguishing smouldering fires in wood, paper, textiles, etc.

- Installed as a total flooding central bank system inclusive a number of distributions

- Normally installed with pneumatic release, but can also be supplied with mechanical, electrical, and manual release

G Fire CO2 systems meet a number of international class requirements, including LRS, DNV, BV, PRS, CCS, ABS, GL, RMRS and NK, as well as national authorities.

Construction

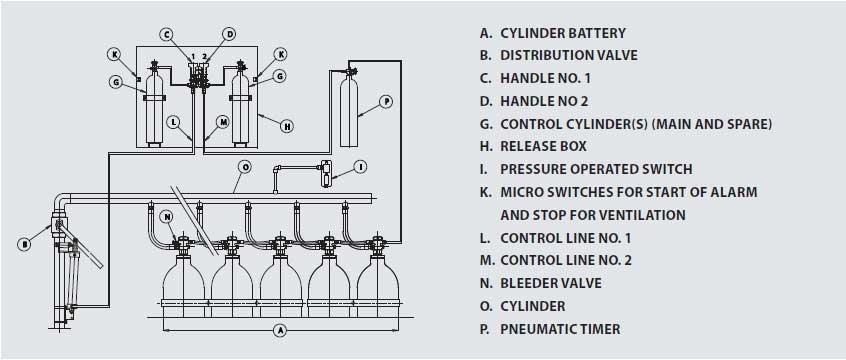

The G Fire CO2 system consists of one or more pressure cylinders containing the extinguishing agent CO2. The cylinders are connected via a common manifold.

From the main manifold, the extinguishing agent is led through distribution valves to the protected spaces.

The valve construction, cylinder size, and cylinder pressure, combined with the computer calculated pipe and nozzle dimensioning, ensures that the extinguishing agent is distributed in correct quantities and within the prescribed time. The release is activated pneumatically, electrically and/or mechanically.

G Fire pressure-operated cylinder valves offer the possibility of connecting CO2 cylinders in groups operated pneumatically from one or more release cabinets equipped with CO2 gas cylinders. The release cabinets are equipped with pilot valves for use in opening cylinders and distribution valves by pipe connections. For pneumatic operation, the built-in actuator is used for each cylinder valve. These are connected to the other cylinder valves in the group via series-connected, flexible high-pressure hoses.

CO2 cylinders

The cylinders are delivered as 67.5-litre steel cylinders filled with 45 kg of CO2. To enable remote control and quick release, the cylinders are supplied with G Fire pressure operated quick opening valves, which also offer the possibility of manual operation.

The valve construction secures against damaging overpressure in the cylinder, as the valve has a built-in bursting disc, activated at a nominal pressure of 190 bar.

CO2 room

The cylinders are normally stored in a separate, well-ventilated and insulated room, where the temperature is kept between 0° and 40°C. The room must have free access to open air. The room should have a minimum clear height of 2.4 m to provide adequate space for the mounting of manifolds and weighing beams for check weighing of the cylinders.

Checking equipment

The cylinders can be checked by a weighing device or liquid level measurement.

Special equipment

To reduce the installation time in CO2 rooms onboard ships, cylinder arrangements mounted in racks consisting of up to 100 pieces of 45/53.6 kg cylinders, complete with manifold and fixing equipment, can be supplied.

CO2 extinguishing system: release system

The pressure controlled cylinder valve

All G Fire release systems are based on the unique pressure operated cylinder valve. This valve is used in all systems in which pressure cylinders (CO2 and N2) form a part. CO2 cylinders, with contents of up to 60 kg discharge, can be released within one minute. Valve housings and internal parts are made of brass or stainless steel, with tightening materials of neoprene or copper.

The valve is constructed as a combined pressure operated quick opening valve with hand wheel for manual opening.

The G Fire valve is designed with a unique function that enables the user to perform a real check of the valve function. By opening the control valve for releasing the cylinders while leaving the distribution valve closed, the manifold will be pressurized. It can then be proved that each valve is opened. By closing the control valve, the release piping system will be relieved and the cylinder valves will close. This function is required by some classes and authorities.

Pneumatic release system

Total flooding systems require groups of cylinders to be released simultaneously. For this purpose, pneumatically operated cylinder valves are used in conjunction with the pilot pressure from the master release box containing control cylinder(s) (CO2 or N2), two control valves, a pressure gauge, and one or two door switches.

As an option, the system can be supplied with a pneumatic time delay device to delay the opening of the main valve. Emergency release from the CO2 room can be made by manually opening the cylinder valve and then operating the two local control valves.